PC Wire Production Line

High-speed straight-line drawing systems engineered for high-carbon steel. Featuring integrated pickling, phosphating, and advanced coating technologies.

Workflow

Production Process

Pay-off & Descaling

Heavy-duty pay-off with mechanical descaling or pickling/phosphating integration.

Wire Drawing

Straight-line drawing machines optimized for high-carbon steel reduction.

Stabilizing

Induction heating or lead-bath tempering for stress relieving and elongation.

Cooling & Tension

Water cooling troughs with PLC-synchronized tension control.

Take-up & Spooling

Precision layer winding and automatic spool changeover systems.

Key Components

PC Wire Line Configuration

Pay-off System

Active pay-off with pneumatic braking and automatic tension control for smooth wire feeding.

Wire Feeding Unit

Precision feeding mechanism with guide rollers for consistent wire path alignment.

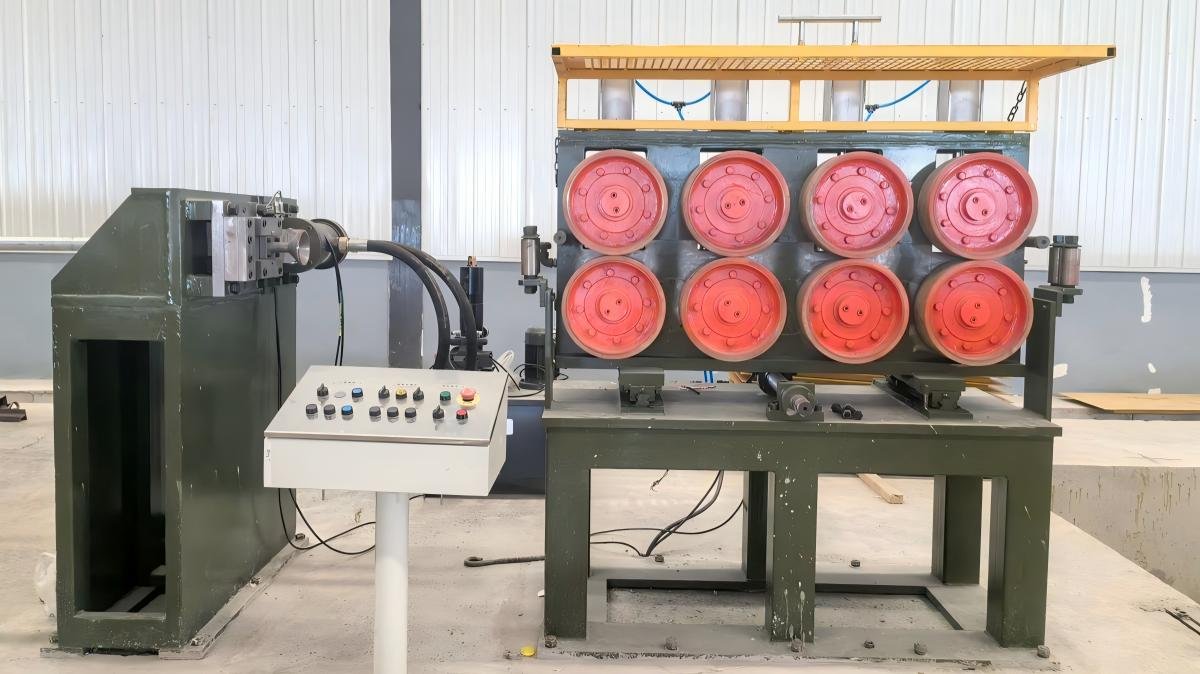

Straightening Machine

Multi-roller straightening system for eliminating wire curvature and stress relief.

Advanced Straightening Unit

High-precision straightening with adjustable roller pressure for optimal wire geometry.

Take-up Machine

Heavy-duty spooler with variable speed control for 1-3 ton coil handling capacity.

Tension Control Wheel

Dancer arm feedback system maintaining constant wire tension throughout the process.

Specifications

Technical

Parameters

Our PC Wire lines are customizable to meet specific ASTM, BS, and EN standards. The parameters below represent our standard high-speed configuration.

- • ASTM A421 (Uncoated Stress-Relieved Steel Wire)

- • BS 5896 (High Tensile Steel Wire)

- • GB/T 5223 (PC Steel Wire)

| Parameter | Value / Range |

|---|---|

| Inlet Wire Diameter | 6.5mm - 14.0mm (High Carbon Steel) |

| Outlet Wire Diameter | 3.0mm - 9.0mm |

| Drawing Speed | Max 12 m/s (Adjustable) |

| Capstan Diameter | 600mm / 800mm / 900mm |

| Stabilizing Method | Induction Heating (IGBT) or Gas Fired Furnace |

| Temperature Control | 350°C - 450°C (±2°C Precision) |

| Relaxation Properties | Low Relaxation (Grade 2) / Normal Relaxation |

| Take-up Coil Weight | 1000kg - 3500kg |

Global Presence

Trusted by Industry Leaders

Integrated PC Production Complex

Full-scale manufacturing facility featuring multiple PC wire and strand production lines with centralized control systems and quality testing stations.

High-Speed PC Wire Production Line

State-of-the-art straight-line drawing equipment with integrated stabilizing and coating systems for consistent high-quality PC wire output.

Start Your Project With JINXIN

Whether you need a single machine or a complete factory layout, our engineers are ready to provide a detailed proposal and ROI analysis.