PC Strand Production Line

Advanced turnkey solutions for manufacturing 1×3, 1×7, and 1×19 Prestressed Concrete Strands. Engineered for high-speed stability, precise tension control, and superior induction tempering.

Production Flow

From raw wire rod to finished PC strand coil.

Pay-off

Active wire paying-off

Surface

Cleaning & Descaling

Drawing

High-speed reduction

Stranding

Skip/Tubular Stranding

Tempering

Induction Stabilizing

Tension

PLC Tension Control

Take-up

Layer Winding

Technical Parameters

Optimized configurations for different strand structures.

Standard PC Strand (1×7 / 1×3)

| Parameter | Model 630 (1×3) | Model 800 (1×7) | Model 900 (1×7) |

|---|---|---|---|

| Strand Diameter | 6.5 - 12.0 mm | 9.53 - 15.24 mm | 12.7 - 17.8 mm |

| Max Speed | 150 m/min | 120 m/min | 100 m/min |

| Pay-off Spools | 3 | 7 | 7 |

| Main Motor | 90 kW | 132 kW | 160 kW |

| Take-up Weight | 3.5 Ton | 4.0 Ton | 5.0 Ton |

Heavy Duty (1×19)

| Parameter | Value |

|---|---|

| Structure | 1+9+9 / 1+6+12 |

| Strand Dia | 17.8 - 28.6 mm |

| Cage Speed | 400 - 600 rpm |

| Stabilizing | 400kW IGBT |

| Application | Bridge Cables, Mining |

1×10 / Other Structures?

We provide custom designs for non-standard strand structures including Compact Strand and Epoxy Coated lines.

PC Strand Manufacturing System

Integrated production line from wire drawing to final strand output with automated control systems.

Line Components

Built with heavy-duty steel and precision engineering.

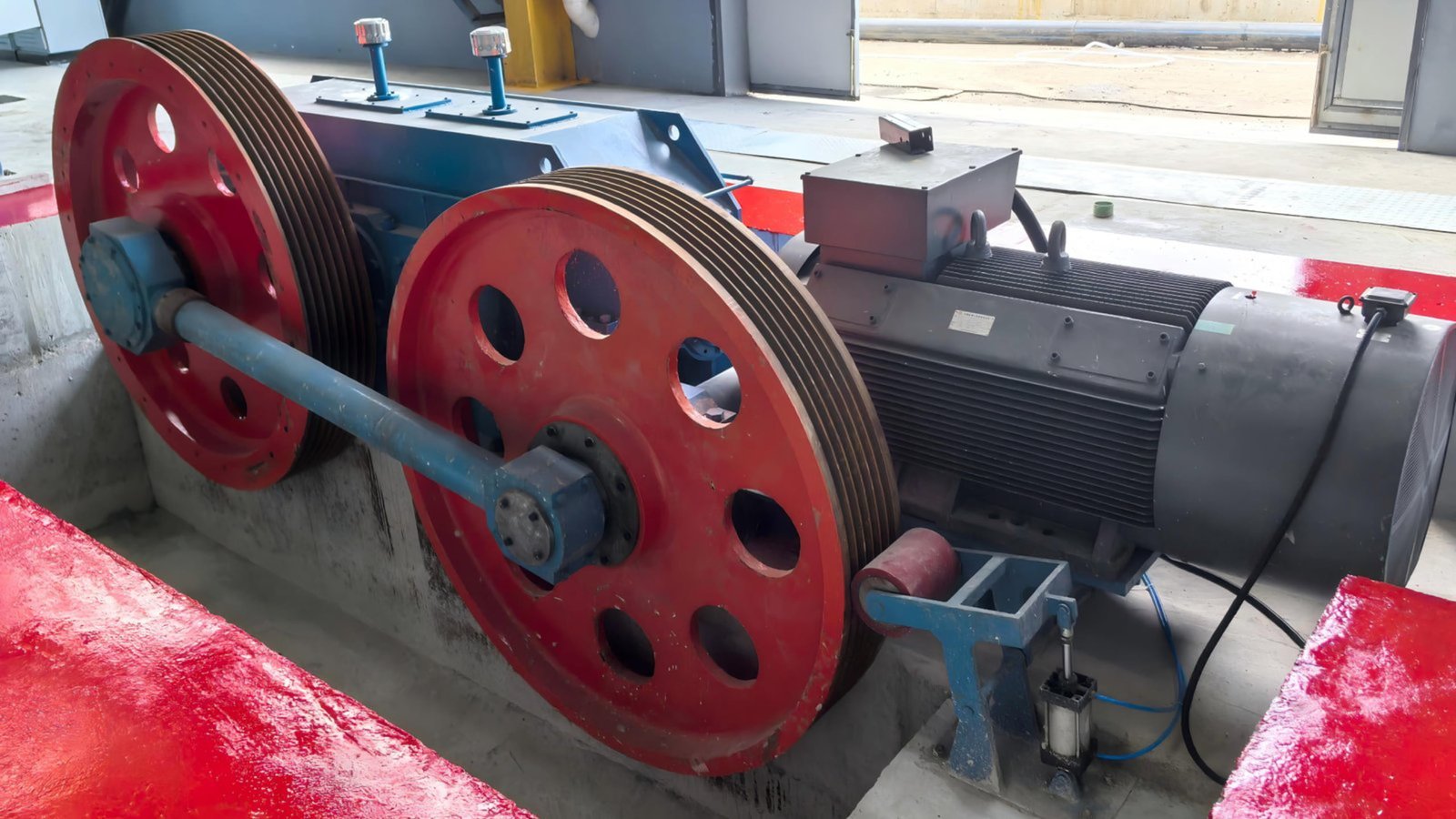

Stranding Part

High-speed skip strander with precision control.

Induction Furnace

IGBT technology for precise temperature control.

Tension Capstan

Pneumatic/Mechanical dual feedback system.

Wire Pay-off

Active pay-off prevents wire entanglement.

Take-up Unit

Ensures accurate wire diameter input.

Synchronizing unit

Perfect layering with automated coil ejection.

Global Deployments

Turnkey Factory Solutions

With over 20 years of expertise, JINXIN Transmission has successfully installed PC steel production lines across Asia, Middle East, and Eastern Europe. We provide:

- ✓ Factory Layout Design: Full CAD workshop planning optimized for logistics.

- ✓ Installation & Training: On-site engineers for commissioning and operator training.

- ✓ Retrofitting: Upgrading legacy lines with modern PLC and induction systems.

"JINXIN's machinery increased our output by 40% while reducing energy consumption by 15%."

-- Leading PC Strand Manufacturer, Turkey

Certified Quality

Start Your Project

Contact our engineering team for a customized proposal and ROI analysis.