Importing PC strand is getting expensive with rising costs and tariffs. This hurts your profits and makes you rely on others. What if you could make it yourself by upgrading your factory?

To upgrade your wire factory for PC strand production, you must first check your existing pre-treatment line, like pickling. Then, confirm your wire drawing machine1 can handle high-carbon steel. Finally, assess your team's experience or plan for training.

I remember a client from South America who faced this exact problem. He owned a wire drawing factory and was also a major importer of PC strand. As shipping costs and anti-dumping tariffs2 on Chinese products went up, he wanted to produce it himself. He came to us at JINXIN for a solution. We worked together, and I broke down the upgrade process for him into a few key questions. These are the same questions you should ask yourself if you are in a similar situation. Let's walk through them one by one.

Do You Have the Right Pre-Treatment Setup for PC Strand?

You want to make high-quality PC strand, but the raw material is not ready. Using unprepared wire rods can lead to poor quality and production problems. A proper pre-treatment line is the essential first step.

A pre-treatment line, especially one with acid pickling, is crucial for PC strand production. It cleans the high-carbon wire rod surface, removing rust and scale. This ensures better drawing performance and a higher quality final product.

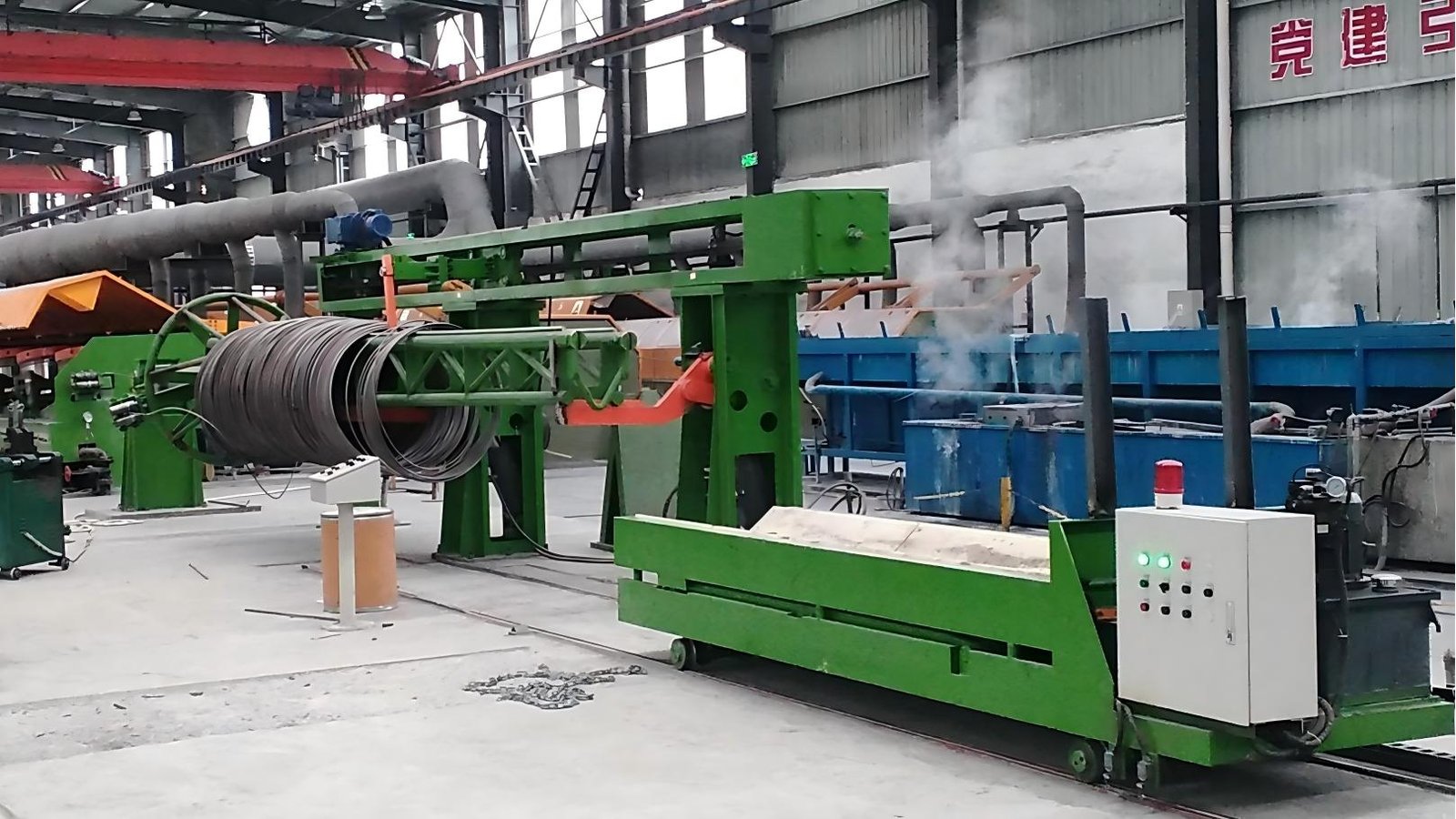

When we start talking about producing PC strand, the first thing I always look at is the beginning of the process: raw material preparation. PC strand is made from high-carbon steel3 wire rods. These rods come from the steel mill with a layer of scale and sometimes rust on the surface. You cannot feed this directly into a drawing machine. It will destroy your expensive drawing dies and result in a very poor-quality wire. This is why a pre-treatment line is not just an option; it's a necessity. The most effective method is acid pickling4. This process cleans the rod's surface perfectly. After pickling, the rod is usually coated with phosphate, which acts as a lubricant carrier for the next step, wire drawing. For my South American client, his existing factory already had a pickling line, which was a huge advantage. It meant we didn't have to build one from scratch, saving him significant time and investment.

| Step | Purpose in Pre-treatment | Impact on PC Strand Quality |

|---|---|---|

| Mechanical Descaling | Removes the thick outer layer of scale. | Reduces acid consumption and pickling time. |

| Acid Pickling | Chemically removes all remaining rust and scale. | Creates a clean surface for perfect drawing. |

| Rinsing | Washes away any leftover acid. | Prevents surface contamination. |

| Phosphating/Coating | Applies a lubricant-carrying layer. | Protects dies and ensures smooth drawing. |

Can Your Current Wire Drawing Machines Handle High-Carbon Steel?

You have wire drawing machine1s, but are they right for PC strand? Using the wrong machine can damage it and produce faulty wire. You must check if your machines are built for high-carbon steel's toughness.

PC strand production requires drawing high-carbon steel wire, which is much tougher than low or medium-carbon steel. You need to check if your existing machines have the motor power, robust capstans, and cooling systems5 needed for this demanding process.

After confirming the pre-treatment setup, the next critical checkpoint is your wire drawing machine. This is where many factories need to invest in new equipment. Drawing high-carbon steel3 is a completely different game compared to drawing low or medium-carbon steel. The material is much harder and has greater tensile strength. This puts enormous stress on the machine. A standard wire drawing machine designed for softer steel will fail. It lacks the motor power to pull the wire, and its components will wear out very quickly. For PC strand, you need a machine specifically designed for high-carbon steel. These machines, like our JINXIN straight-line wire drawing units, have powerful motors, extremely durable capstans, and a very efficient cooling system. The cooling is especially important because the drawing process generates a lot of heat, which can affect the wire's properties. My client’s existing machines were only for low-carbon wire, so we had to add a new high-carbon drawing line to his project plan.

| Feature | Low/Medium-Carbon Drawing Machine | High-Carbon Drawing Machine (for PC Wire) |

|---|---|---|

| Motor Power | Standard | High Torque / High Power |

| Capstans | Standard Hardness | Tungsten Carbide Coated (High Wear Resistance) |

| Cooling System | Air or basic water cooling | High-efficiency internal and external water cooling |

| Drawing Speed | Can be high | Controlled speed with powerful transmission |

| Dies | Standard Dies | High-quality Tungsten Carbide or PCD Dies |

Is Your Team Ready to Manage PC Strand Production?

You can buy the best equipment, but who will run it? An inexperienced team can lead to low efficiency, high waste, and safety risks. Having operators with PC strand experience can make the transition smooth.

An experienced team is a huge asset when adding PC strand production. They understand the specific machine settings, quality control checks, and safety protocols. This knowledge helps reduce the learning curve, minimize waste, and ensure consistent, high-quality output from day one.

Equipment is only half of the equation. The other half is the people who operate it. Producing PC strand is a precise science. It is not a "set it and forget it" process. Your operators need to understand the nuances of the machinery. For example, on the stranding machine, they need to set the correct tension and lay length to produce a stable strand. On the stabilizing line, they need to control the heating and cooling temperatures perfectly to achieve the required mechanical properties like low relaxation. An experienced team already has this knowledge. They can get a new production line up to target efficiency much faster. They also know how to spot potential problems before they lead to major breakdowns or quality issues. When I discussed this with my client, he was concerned because his team only had experience with basic wire drawing. This is a common challenge, but it is one that has a clear solution.

| Role in Production | Key Skills for PC Strand | Why It's Important |

|---|---|---|

| Machine Operator | Understands tension control, die changes, stranding parameters, and temperature settings. | Ensures consistent product quality and machine efficiency. |

| Quality Control Tech | Proficient in tensile testing, relaxation testing, and dimensional checks. | Guarantees the final product meets international standards (ASTM, BS, etc.). |

| Maintenance Engineer | Knows the specifics of high-torque motors, gearboxes, and induction heaters. | Minimizes downtime through preventative maintenance and quick repairs. |

What If You Don't Have an Experienced Team for PC Strand?

You lack a team with PC strand experience, and it is holding you back. The fear of a long, costly training process might stop your expansion plans. Don't worry. The right equipment partner provides comprehensive on-site training.

If you don't have an experienced team, it is not a problem. A good supplier, like us at JINXIN, provides complete on-site training. Our technical experts will guide your team through every step during the installation and commissioning phase.

"On-site Technical Training")

"On-site Technical Training")

This was the final piece of the puzzle for my South American client. He had the factory space and the ambition, but not the experienced team. I told him this is not a deal-breaker. In fact, for most of our turnkey projects, we assume the client will need training. This is a core part of our service. When we supply a production line, our technical experts travel to your site for installation and commissioning. But their job doesn't end there. They stay to provide intensive, hands-on training for your operators and maintenance staff. We teach them how to run the machines, how to perform quality checks, and how to do routine maintenance. We don't just show them which buttons to press. We explain the "why" behind each step so they understand the entire process. By the time our experts leave, your team is not just trained; they are confident and fully capable of running the new line efficiently. This commitment to training ensures your investment starts paying off from day one.

| Training Phase | What Your Team Learns | Outcome for Your Factory |

|---|---|---|

| Week 1: Safety & Basics | Machine safety protocols, component identification, basic operational theory. | A safe and knowledgeable foundation for all staff. |

| Week 2: Operation | Hands-on operation of drawing, stranding, and stabilizing lines. Setting parameters. | Operators can run the full production line independently. |

| Week 3: Quality Control | Using testing equipment, understanding quality standards, and interpreting results. | Your team can guarantee product quality and compliance. |

| Week 4: Maintenance | Routine checks, lubrication, troubleshooting common issues, changing wear parts. | Reduced downtime and a longer lifespan for your equipment. |

Conclusion

Upgrading your factory for PC strand is a big step, but it is achievable. With the right equipment, planning, and partner support, you can successfully expand your production capabilities.

Knowing the necessary features helps in selecting the right machine for efficient and quality production. ↩

Understanding these tariffs can help businesses navigate international trade challenges effectively. ↩

High-carbon steel is tougher, requiring specialized equipment, making it vital to understand its demands. ↩

Acid pickling cleans wire rods effectively, ensuring better drawing performance and higher quality products. ↩

Efficient cooling systems prevent overheating, maintaining wire quality and machine longevity. ↩