High Carbon Wire Drawing Line

Precision-engineered wire drawing solutions for high-carbon steel processing. Advanced cooling systems and low-vibration performance for superior wire quality.

Component Showcase

High Carbon Wire Drawing Line

Precision-engineered components working in perfect harmony to deliver superior wire drawing performance and quality.

Pre-treatment System

Advanced surface preparation unit ensuring optimal wire conditioning before the drawing process begins.

Phosphating & Boronization

Electrical phosphating and boronization system for enhanced wire surface treatment and drawing lubrication.

Drawing Drums

Precision-balanced drawing drums with advanced tension control for consistent wire diameter and quality.

Drawing Assembly

Multi-stage drawing drum assembly with integrated cooling and lubrication systems for optimal performance.

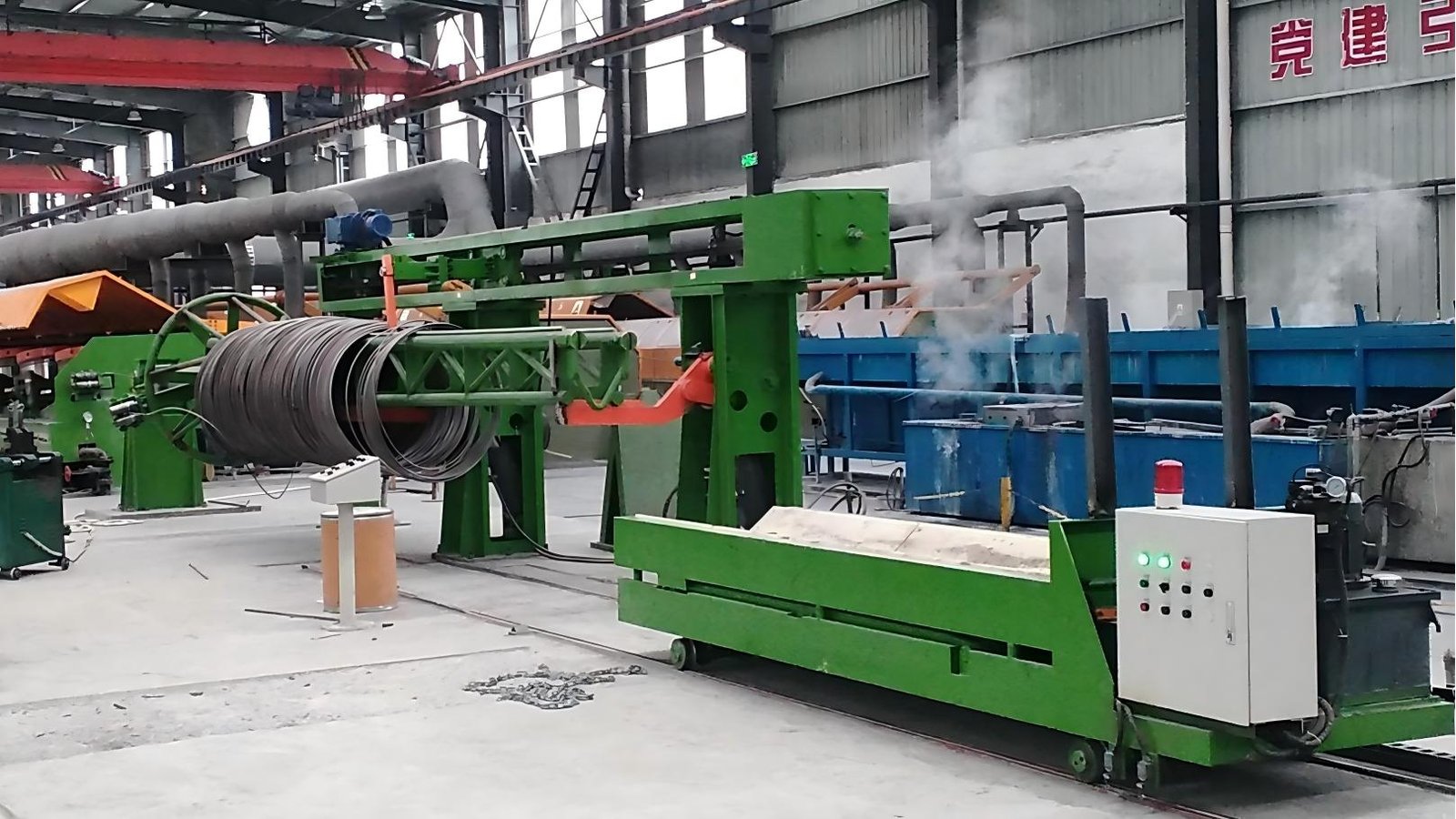

Pay-off System

Heavy-duty pay-off system with PLC-controlled tension management for smooth wire feeding and processing.

Mechanical Pickling

Automated mechanical pickling unit for efficient scale removal and surface preparation of high carbon wire.

Technical Data

Product Specifications

Wire Diameter Range

Drawing Speed

Machine Types

- Straight-line Drawing Machine

- Inverted Vertical Drawing Machine

- Multi-pass Drawing Line

Power & Control

Applications & Benefits

Primary Applications

PC Wire Production

High-carbon steel wire for prestressed concrete applications

Spring Steel Wire

Precision drawing for automotive and industrial springs

Tire Cord Wire

Ultra-fine wire drawing for tire reinforcement applications

Key Benefits

Production Process

Drawing Process Flow

Wire Feeding

High-carbon steel wire rod input with automated pay-off system

Drawing Process

Multi-pass drawing through precision carbide dies with lubrication

Cooling & Treatment

Advanced cooling systems maintain optimal temperature control

Coiling & Packaging

Automated coiling system with precision tension control

Get Your

Quote Today

Ready to upgrade your wire drawing capabilities? Contact our technical team for customized solutions.

Why Choose JINXIN?

20+ Years Experience

Founded in 2004, serving global wire drawing industry

90% Market Share

Leading supplier in China's PC steel production market

Turnkey Solutions

Complete factory planning, installation, and commissioning

Global Standards

ASTM, BS, EN compliant equipment and processes